Recently, a lot of emphasis has been laid on personalized nutrition corresponding to an individual’s body needs and health status instead of general nutritional requirements. That’s why food researchers and industrialists have started leading the food creation according to the consumer’s nutritional requirements. In fact, the nutritional function of food materials not only relies on the presence of proteins, carbohydrates, lipids, vitamins, minerals, and other metabolites but also on the chemistry of organization and interaction among these component structures. Several studies have shown that hindrances to the absorption of minerals and vitamins are associated with the intake of these nutrients in fortified food. For example, phytates and phytic acids can reduce iron absorption, whereas iron and oxalates lower calcium absorption. In contrast to conventionally prepared fortified food, 3D food printing manufactures food products that ensure more accurate calculation of calorie intake, fill specific nutrient gaps, and offer the least hindrance to nutrient bioavailability.

How 3D printing works in food manufacturing

3D printing is a digitally controlled process which manufactures solid objects with complex structure by converting 3D data to sequential deposition of materials in layers. The structure to be printed is loaded in the software as the input file, which then allows the flow of materials through nozzles to settle layer by layer to build objects.

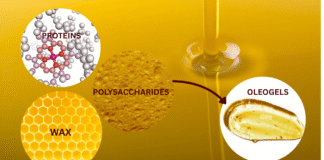

The material used for printing is called bioink, which has a viscosity low enough to flow out and high enough to stick to previously deposited layers. The selection of the constituents for formulating bioink is based on the specific properties of these constituents. For example, fat-based ingredients provide lubrication, starch-based ingredients are responsible for viscosity, while protein-based ingredients can develop gels.

3D Food Products in the market

The leading Italian pasta manufacturer, “Barilla, ”in collaboration with a Dutch scientific research firm (TNO), enabled customers to 3D print their pasta with different shapes. Likewise, a British start-up, “Nourished,” launched a customized daily nutrition stack of 3D gummies. The customers were able to choose seven nutrients out of 28 to create their own stack. In an attempt to achieve personalized nutrition for diabetic patients, 3D-printable food ink was formulated using food ingredients with a low glycemic index (wheat bran, milk powder, and mushrooms). The effectiveness of food was verified by monitoring the blood glucose levels.

3D Food Products with bioactive compounds

In the last few decades, the trend of incorporating natural plant ingredients (containing bioactive molecules) into food has been growing. But incorporation of bioactive functional ingredients is quite challenging, as their activity is reduced during the processing of food. 3D printing allows encapsulation of bioactive molecules in 3D printed layers of food to protect them from degradation. Antioxidant-rich cookies were prepared by incorporating grape seed polyphenols in 3D-printed layered cookies.

3D food with probiotics

Several studies have witnessed that the consumption of probiotic bacteria is crucial for maintaining a healthy gut environment, but the stability of probiotics is a major concern in formulating food recipes, as it decreases due to food processing or storage. In a recent study, the possibility of incorporating probiotics into 3D printed mashed potatoes and the effect of storage on their stability has opened a new dimension in the development of functional foods using 3D printing.

3D food printing is revolutionizing how we approach food production and nutrition. With input from nutritional experts, this technology can create customized food that could deliver personalized nutrition, addressing individual dietary needs. This emerging field of research also provides opportunities to explore the functionality of food ingredients and tackle issues related to health, safety, and overall well-being.

For Further Readings

- Achieving personalized nutrition for patients with diabetic complications via 3D food printing

- Perspective approaches of 3D printed stuffs for personalized nutrition: A comprehensive review

- Extrusion-based food printing for digitalized food design and nutrition control

- Structuring food to control its disintegration in the gastrointestinal tract and optimize nutrient bioavailability